Metal bending equipment is essential for shaping metal sheets and bars into precise angles and curves. It includes tools like press brakes, tube benders, and roll benders, each designed to handle different types and thicknesses of metal. The right equipment allows operators to achieve accurate bends quickly and efficiently, improving both quality and productivity.

These machines vary in complexity from manual devices for small projects to fully automated systems for industrial use. Understanding the specific requirements of a project helps in selecting equipment that balances capability, cost, and ease of use.

With advancements in technology, metal bending equipment has become more precise and versatile. This evolution supports faster production times while meeting tighter tolerances across various industries.

Types of Metal Bending Equipment

Metal bending equipment varies by operation method, capacity, and level of automation. Some machines rely on manual effort, while others use hydraulic power or computerized controls. Each type suits different production scales and precision requirements.

Manual Bending Machines

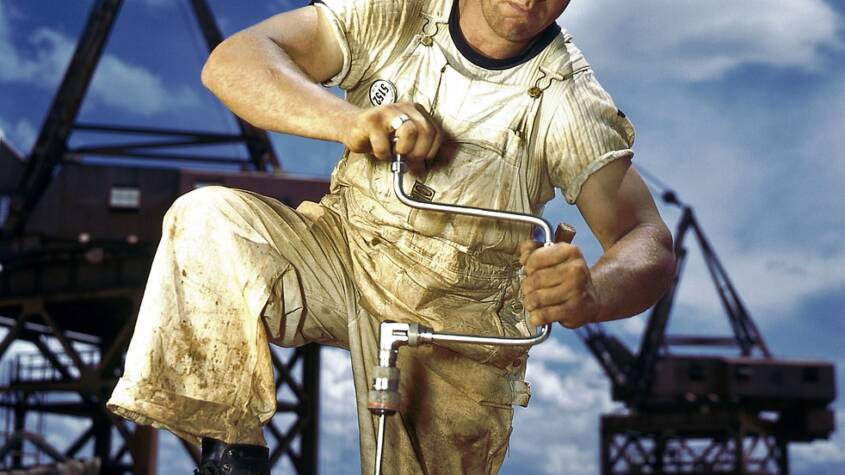

Manual bending machines operate through physical force applied by the user. Common examples include hand brakes and lever-operated benders. These machines are suitable for simple bends and small-scale tasks.

They are typically lightweight, portable, and cost-effective. However, they require physical strength and skill to achieve consistent angles. Manual benders are often used in workshops or for field repairs where quick, straightforward bending is needed.

Their main limitation is lower capacity and precision compared to powered machines. Manual bending is ideal when dealing with thinner metals and smaller batches.

Hydraulic Press Brakes

Hydraulic press brakes use a hydraulic system to generate force for bending metal sheets. They provide significantly greater power and control than manual machines.

These machines are common in industrial settings because they handle thicker materials and larger workpieces efficiently. Operators control the bend angle and depth more precisely than with manual benders.

Hydraulic press brakes can be single or double-acting. They often feature adjustable back gauges for repeatable bending angles. Their power allows bending metals up to several centimeters thick with minimal operator effort.

Hydraulic systems require routine maintenance to ensure reliable operation and safety during heavy use.

CNC Bending Machines

CNC bending machines integrate computer numerical control for automated and highly precise metal bending. Operators program the desired bends, and the machine follows exact instructions.

They are best suited for high-volume production with complex bend sequences. CNC machines reduce human error and increase repeatability across parts.

These machines can handle a wide range of metal types and thicknesses due to advanced tooling and sensors. Setup time is longer but payoffs come with consistent quality and efficiency.

CNC bending equipment often includes features like automatic tool changers and real-time angle feedback, improving productivity and reducing waste.

Key Features and Applications

Metal bending equipment focuses on accuracy, process speed, and adaptability to different metals. These factors determine its suitability for various industrial and commercial tasks.

Precision and Accuracy

Metal bending machines use controlled forces and precise angle measurements to ensure consistent bends. CNC (Computer Numerical Control) technology allows operators to program exact specifications, reducing human error.

This precision is critical when components must fit tightly or meet strict engineering standards. Tolerances are typically within tenths of a millimeter, which supports high-quality fabrication.

Accurate bending minimizes material waste and shortens post-processing work.

Automation and Efficiency

Modern metal bending equipment often integrates automation to optimize production. Automated systems can perform repetitive bending tasks continuously without fatigue or variation.

Automation decreases cycle times and increases output rates. It also allows for quick adjustments between different bending angles or product types without manual recalibration.

These machines often feature automatic material loading and unloading, which reduces labor costs and improves workplace safety.

Material Compatibility

Metal bending equipment must handle a range of metals, including steel, aluminum, copper, and titanium. Equipment design considers metals’ hardness, thickness, and ductility.

Adjustable tooling and pressure settings allow bending of both soft and hard metals without causing cracks or deformation. Some machines are specialized for thin sheets, while others accommodate thick plates.

Compatibility with different metal types enhances versatility across industries such as automotive, aerospace, and construction.

Lawn Care in Oakville: Expert Tips for a Healthy, Green Yard

Lawn care in Oakville requires attention to the region’s unique climate and soil condition…